Ms Laser Cutting Price

A cooling system is a water chiller that cools the machine. The electro-optical conversion rates are 33% and 67% respectively. Heat energy is converted at about 67%. To ensure normal operation, the chiller must be cooled with water in order to lower the temperature.

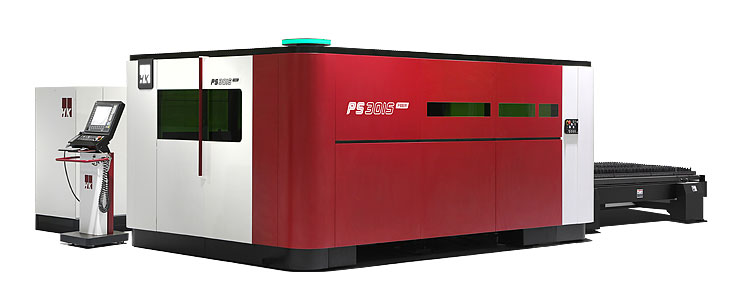

GSS Machinery highspeed CO2 lazer machines come in a range of configurations to match your budget and process needs.